UTABE GmbH

Environmental Technology, Automation & BioEnergieThe Company

Environmental Protection Technology, Automation Energy

The Company UTABE GmbH is specialized to Construction, Consulting and Operations Supervision of Environmental Projects.

⚘

⚘

Focal points of our activities are:

- Construction and operating supervision of municipal wastewater treatment plants.

- Energy production of Biogas and Solar Plants.

- Processing of industrial waste water.

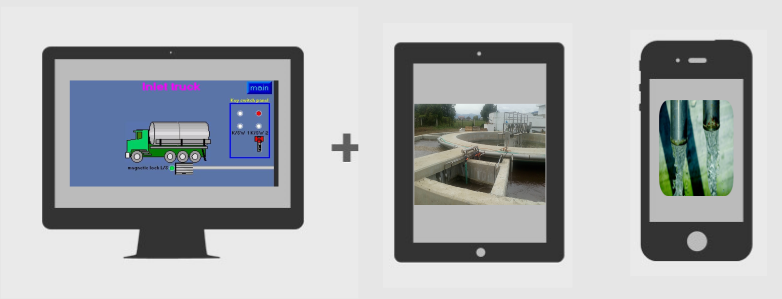

- Automation (PLC)

INFRASTRUCTURE

The company UTUBE GmbH has a team of qualified engineers and experted scientists in the field of environmental protection, Chemicals, Mechanicals, Electricals, Biologists and Civil Engineers. With their longtime and wide-ranging experience our employees can be offered comprehensive disposal solutions which meet the requirements of the customer.

COMPANY'S MAIN GOALS

Our philosophy is to build environmental projects with innovative technologies.

Attention to detail - guarantee for an excellent performance.

Consistency, reliability, and building a long-term relationship.

Project design should be environmentally friendly and cost-effective.

Full customer satisfaction by maintaining high quality and safety measures.

Compreactor ®

Wastewater Treatment Plants

COMPREACTOR ® is a specific compact construction of Wastewater Treatment Plant made by reinforced concrete, including all the necessary treatment stages for applications from medium to large plants.

The plant does not contain a pretreatment stage through the DAF, but the wastewater enters directly into the "polymorphic" ventilation.

Important Characteristic of Compreactor‘s ® is, the proposed polymorphic aeration process achieves an extreme endogenous respiration leading to extreme results.

Basic Compreactor ® Advantages:

- Lower reinforced space/land demands.

- Lower reinforced concrete demands.

- Central machinery control station attached to Compreactor ®, with most of the necessary equipment and electrical board inside.

- Less wiring, piping and pumping demand.

- Chemical dosing unit and management inside the control station.

- Aeration unit via a “closed cyclical circuit” with air equipartition.

- Sludge treatment and feeding stages inside the control station.

The basic operation features are:

- High Mixed Liquor Suspended Solids MLSS concentration (~20.000 mg/L) in the aeration tank.

- Hoher hydraulischer Aufenthalt zu dem Abwassertank mit einer niedrigen Feststoffaufenthaltszeit.

- High recirculation rate (~1000%).

- Operational “concurrency” of the aeration and sedimentation tanks.

- The sludge age reaches “infinity”, as a result of the low sludge excess.